SiteMap

close

Research

Research News

A prestigious global university that fosters Sejong-type talent who challenges creative thinking and communicates with the world.

|

Trends in the Development of Brilliant Color Alloy Technology 2023.09.05 159 |

|

|---|---|

|

Trends in the Development of Brilliant Color Alloy Technology Professor Kim Ki-beom, Department of Nano Materials Science and Engineering, Sejong University

1. Introduction

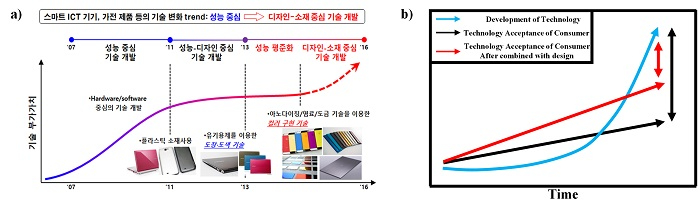

Figure 1. a) Changing trend of technology added value over time, b) Correlation between technology development and consumer acceptance [1] As we enter the era of the Fourth Industrial Revolution in the 21st century, consumption patterns have changed from rational to emotional consumption (Figure 1-a). Thus, the vision and development direction of technology development is shifting from technology-centered to human-centered, from independent technology to convergence technology. Materials are now created with the aim of arousing favorable emotions and impressions in consumers by providing stimulation or information suitable for their desired emotions. In other words, it satisfies the emotional needs of consumers by providing not only material stimulation, but also sensory information about their needs. [2-4] The aforementioned emotional approach to new technology development can resolve the gap between consumer demand and technology, one of the problems of modern technology development. This can be seen The Innovator's Solution, written by Christensen and Raynor. Simply put, technology grows exponentially, and consumer demand increases, widening the gap between the two figures. To solve this problem, various methods have been proposed, among which technology convergence is proposed, and the convergence of design and engineering technology is also suggested as another approach (Figure 1-b) [1]

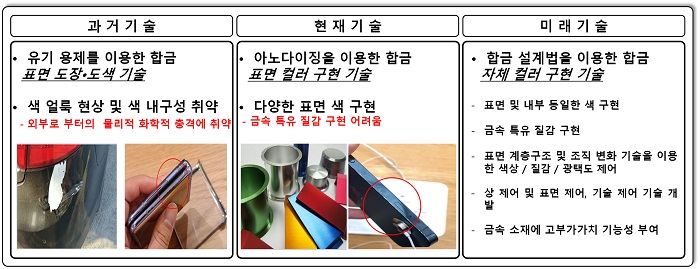

Figure 2. Flowchart of technology development of realizing metal color The metal industry began to develop alloy design technology and technology that combines design such that various colors are realized on the metal surface to maximize the function of emotional materials by stimulating sight, the most sensitive sense of the human senses. Various surface treatment technologies have been developed, ranging from color realization using organic solvents, which have been used for a long time, to anodization using a variety of current chemical reactions.[2] Despite its advantage of being able to show various colors, this process has the disadvantage that it is not free from external physical and chemical influences, causing the color realization layer to be damaged and discolored. In order to compensate for these shortcomings, a metal having color on the surface and inside, that is, a metal having its own color, was developed through alloying for the realization of a metal having a permanent color. In general, most metals except gold, silver, and copper have a glossy achromatic color, so the electronic structure of the metal itself is deformed through alloying, and special optical properties are realized. Color alloys of various colors were developed using the high solubility of metals or through new compounds between metals. 2. Current status of domestic and foreign research In 2015, the Korea Institute of Industrial Technology developed an emotional material technology that could maximize customer satisfaction by realizing an alloy with color, brightness, and complex color without using surface treatment such as colored paint or plating. The institute developed an alloy by mixing two types of metal elements and adding one metal through tunneling to realize insufficient mechanical properties. As metal elements, color alloys using various metals/non-metals such as copper, titanium magnesium, zinc, and silicon were developed, and color coding was also carried out. Typically, various colors and brightness of each alloy were realized through composition control and surface shape control of Cu-X (Sn, Zn, Si, Ni)-based color alloys. [5]

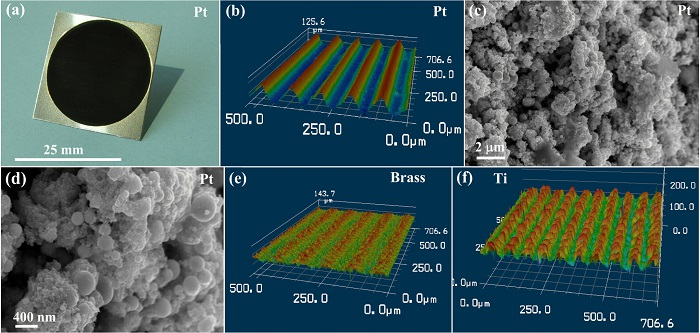

Figure 3. Color alloy being coded (excerpt from an interview with Korea Institute of Industrial Technology) The Institute of Optics at the University of Rochester has developed a technology to control the reflectivity of metals using femtosecond laser surface structuring technology. According to the research contents presented, the institute developed an optical property control technology from the ultraviolet region to the terahertz region, and developed the so-called black metal with a black surface color. This technology has the advantages of less generated contamination during the process and simple handling of complex shapes. The aforementioned femtosecond laser pulse technology enables the formation of hierarchical nano and micro structures, realizing a multifunctional metal surface, and these structures have the effect of greatly improved light absorption in a wide range, superhydrophobicity, and self-contamination removal. In addition, the research results reported that additional functions such as anti-corrosion and anti-freezing can be formed. Therefore, it is considered that this study has great potential to be applied to more diverse technological applications than the existing surface treatment process [6, 7]

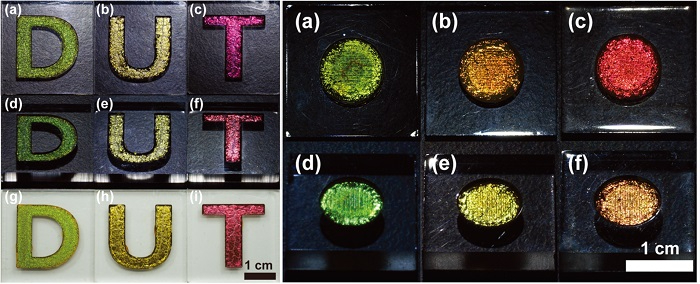

Figure 4. Colored metals and microstructures with superhydrophobicity The State Key Laboratory of Fine Chemical at Dalian University of Technology attempted to develop low angle-dependent structural colors using structurally colored materials. In the case of structural colors using spheres made of materials with high refractive index, the effect between the incident-viewing angles on color may be weaker than that of commonly used materials, so the researchers attempted to realize a vivid color under natural light as well as a white background by realizing a structural color with low incident-viewing angles. This study secured the possibility of alleviating the angular dependence of the structural color according to the increase in the diameter of the polycrystalline spherical material. In addition, researchers discovered the color effect and light saturation prevention properties according to the material. [8]

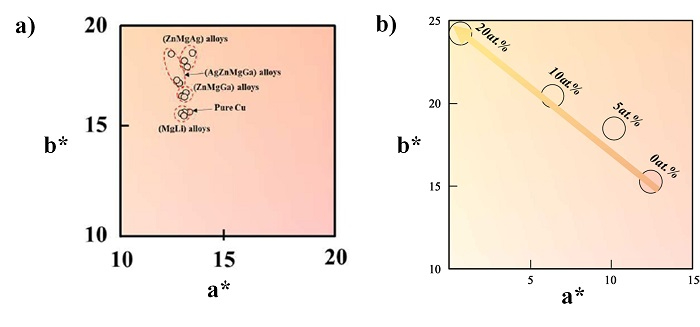

Figure 5. Colored materials for each angle using photonic crystals 3. Development of color alloy using high solubility of metal One way to realize a color alloy is to add another metal to a metal to form a metal solid solution alloy. A typical example is a copper alloy. Various metals such as zinc and magnesium were added to a copper alloy to develop color alloys with various properties. The unique color of copper is due to the special electronic structure of copper, which occurs through the interaction between electron transition and external visible light on this structure.[9] Thus, the characteristics of the copper alloy can be controlled depending on the type and amount of added element, and the reflectivity of a specific region in the visible light region is emphasized to have a special color. It has been reported that the rose gold color used for the exterior of mobile phones and various decorative materials was also developed using copper alloy, and that the color and intensity can be controlled by adjusting the elements added. [10, 11]

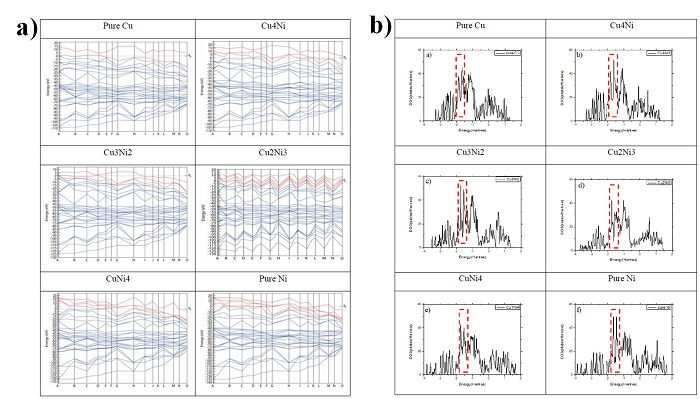

Figure 6. a) Rose gold alloy according to composition and chromaticity, b) Chromaticity for each composition of Cu-Zn alloy Since the theory of color realization using copper alloy has been clarified through experiments, color realization-related theories began to be clarified based on the electromagnetic properties of metals. In order to predict the reflected light due to the interaction between the free electrons of the metal and the visible light incident from the outside, data measurements using a simulation program were conducted, and a theory was clarified through comparison with the reflectance measurement data of real metals. A simulation experiment between the electronic structure of Cu-Ni color alloy and visible light was carried out, and a comparative analysis with actual alloy data found that the electrical structure of the alloy changes depending on composition, and the reflection of absorbed light changes.[12]

Figure 7. a) E-Band structure image of Cu-Ni alloy, b) Density of State graph of Cu-Ni alloy

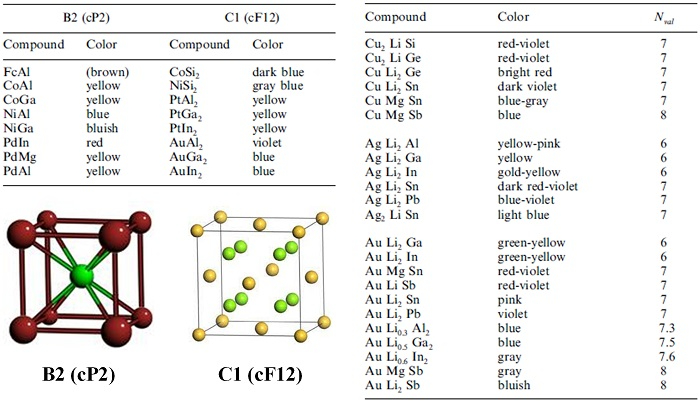

4. Development of color alloy using an intermetallic compound with its own color A color alloy using the solid solubility of a metal is usually a color alloy having a single phase, and a color alloy using an intermetallic compound with its own color is an alloy having multiple phases. An intermetallic compound is a compound that is formed between metal elements based on a constant stoichiometric ratio. When the intermetallic compound has a crystal structure of high symmetry, it has reflected light in a specific wavelength band and expresses a special color. These intermetallic compounds were developed in consideration of binary and ternary elements, the number of electrons in the outermost shell of the alloy, and the crystal structure. In the future, technologies for developing such intermetallic compounds or applying previously developed alloys will be developed. [9, 13]

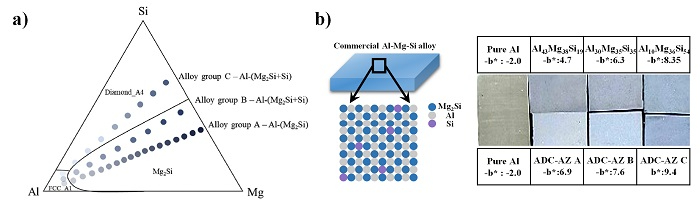

Figure 8. Currently developed binary and ternary color intermetallic compounds [13] It can be seen that the hardness of the intermetallic compound is significantly increased compared to that of the existing metal element as the metal atoms bond in a specific direction. However, alloy has strong brittleness in general because the bonding force in certain crystal directions is extremely reduced.[13] Therefore, it is impossible to apply the intermetallic compound having a special color to other industrial fields, resulting in research to control the mechanical properties through composition control. In order to solve the aforementioned problems, one researcher developed an alloy that can crystallize an intermetallic compound on a metal with machinability and realize metallic luster and special colors throughout the alloy. This technology was developed with the motif of the juxtapositional mixture technique, which makes two adjacent colors appear visually mixed through repetition. The Al-Mg-Si ternary blue color alloy has a color in which the colors of Al and Mg2Si phases are mixed through the crystallization control of the Mg2Si intermetallic compound having a blue color. In this alloy, the blueness and hardness increased as the volume fraction of Mg2Si increased, and the blueness and hardness increased according to the formation of the Si single phase. [9, 14] In addition, research was conducted to improve the properties of Al-Mg-Si using Al (ADC12) and Mg (AZ91)-based commercial alloys, resulting in the development of an alloy with very similar properties to existing alloys but with increased blueness. This study could be utilized as a technology for reducing the cost of existing alloys and recycling waste metal resources, showing the potential for improving the properties of color alloys to be developed later using existing commercial alloys.

Figure 9. a) State diagram of Al-Mg-Si ternary alloy, b) Comparative schematic diagram of alloy using pure element and using commercial alloys [14] 5. Conclusion Recently, technology has developed rapidly, and new and innovative technologies have been developed through convergence between technologies to satisfy the diverse needs of consumers. Among them, emotional materials have become one of the main products that stimulates human senses, allowing consumers to differentiate and purchase the products. Even within the metal industry, various emotional materials that can accept the paradigm of ‘technology + emotion’ and satisfy the senses of consumers have been developed. As a special color is realized on the metal surface, the metal material has changed into one emotional material that can visually satisfy the needs of consumers. As various surface treatment processes have been developed, the color layer embodied on metal surfaces has various colors and properties. However, the color layer embodied on the surface is not free from external influences and is often discolored or destroyed, losing the very unique properties it was purchased for. Relatively free from the preceding surface treatment process, a color alloy has a semi-permanent color as an alloy with its own color. We could develop alloys with various colors and properties using the high solubility of metals and intermetallic compounds. A color alloy using a solid solution alloy has the advantage of excellent workability; however, it has a disadvantage that the color realization range is relatively limited compared to that of an alloy using an intermetallic compound. A color alloy using an intermetallic compound has the advantages of high strength and distinct, diverse colors; however, it has a disadvantage such that workability is very insufficient due to strong brittleness. Innovative research can complement the shortcomings of each realization method and emphasize the advantages is in progress, and it is believed that various application technologies for the commercialization of color alloys will be developed. In addition, various studies on specific color realization mechanisms of color alloys are in progress, which is believed to greatly affect the metal material market by expanding the existing application fields according to more free property control. 6. References [1] C. Christensen, M. Raynor, The Innovator's Solution: Creating and Sustaining Successful Growth, Harvard Business Review Press 2013. [2] J. Han, P. Kim, H.-S. Kim, Study on surface processing design of aluminum alloy materials that is applied to IT and electronics, Journal of the Korean Crystal Growth and Crystal Technology 27(4) (2017) 212-219. [3] N.-C. Park, S.-W. Jeong, Extraction of representative emotions for evaluations of tactile impressions in a car interior, Science of Emotion and Sensibility 16(2) (2013) 157-166. [4] S. Kim, K. Nah, The Development Direction of Emotional Materials by Increasing Sensorial Experiences–Focusing on the Case Study of CMF Design, Archives of Design Research, 27 (2) 27(2) (2014) 121-135. [5] K.I.o.I. Technology, Development of Color Materials for Emotional Sense, (2014). [6] A. Vorobyev, C. Guo, Multifunctional surfaces produced by femtosecond laser pulses, Journal of Applied Physics 117(3) (2015) 033103. [7] A.Y. Vorobyev, C. Guo, Colorizing metals with femtosecond laser pulses, Applied Physics Letters 92(4) (2008) 041914. [8] X. Su, H. Xia, S. Zhang, B. Tang, S. Wu, Vivid structural colors with low angle dependence from long-range ordered photonic crystal films, Nanoscale 9(9) (2017) 3002-3009. [9] S.H. Hong, S.C. Mun, G.C. Kang, H.J. Park, Y.B. Jeong, G. Song, K.B. Kim, Recent development of coloring alloys, Progress in Materials Science 123 (2022) 100811. [10] Y.B. Jeong, S.H. Hong, H.J. Park, Y.S. Kim, Y.J. Hwang, Y.H. Lee, K.B. Kim, J.T. Kim, Investigation of color change in Cu-Zn alloys by reflectivity and color difference analysis, Journal of the Korean Institute of Metals and Materials 56(3) (2018) 171-176. [11] Y.B. Jeong, J.T. Kim, S.H. Hong, H.D. Lee, S.Y. Choi, K.B. Kim, Compositional tuning-induced permanent color adjustment and mechanical properties: binary Cu-Mg colored metallic system, Materials & Design 175 (2019) 107814. [12] S.C. Mun, Development of coloring Cu-based and Al-Mg-Si alloys using concepts of transition energy and juxtaposition, Graduate School of Sejong University, Seoul, 2021. [13] J. Westbrook, R. Fleischer, Intermetallic Compounds, Volume 3, Progress, Intermetallic Compounds, Volume 3, Progress, by JH Westbrook (Editor), RL Fleischer (Editor), pp. 1086. ISBN 0-471-49315-5. Wiley-VCH, June 2002. (2002) 1086. [14] S.C. Mun, G.C. Kang, Y.B. Jeong, H.J. Park, Y.S. Kim, S.H. Hong, G. Song, K.B. Kim, Development of coloring alloys: Color Design for Lightweight Al-mg-Si alloys, Materials & Design (2021) 109449. |

|

| Next | Professor Sikandar Aftab Published Groundbreaking Research in the Prestigious Journal ACS Nano |

| Previous | Vertical Graphene on a Flexible Substrate |